The Technology

Natural gas liquefaction technologies for capacity up to 0.5 MTPA include the following processes:

- AP-SMR™ (0.3 - 0.5+ MTPA)

- AP-C1™ (0.05 - 0.5+ MTPA)

- AP-N™ (0.05 - 0.5+ MTPA)

The Equipment

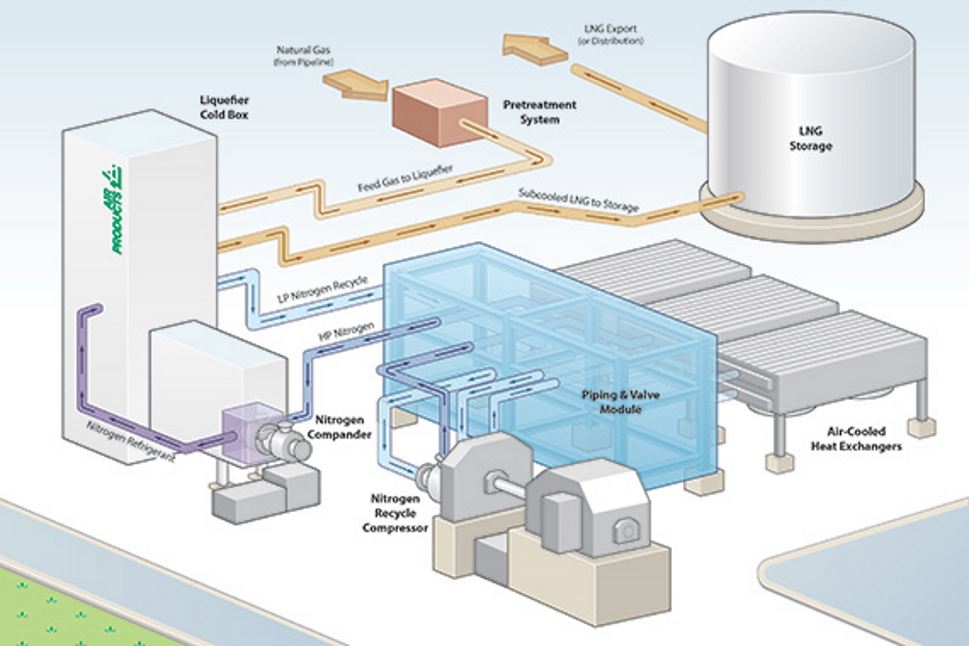

Depending on the process used, natural gas liquefaction equipment can include:

- Standard or custom design liquefier unit

- Cold boxes or coil wound heat exchangers (CWHE) for efficient and reliable liquefaction

- Proven turbomachinery with high efficiency and robust design

- Refrigeration compressors and drivers providing the best efficiency and reliability

- Supporting process systems

- Pretreatment system for gas clean-up

- On-site refrigerant generation and storage

- Vacuum jacketed LNG storage

- LNG truck loading station

Technical Articles & Whitepapers

Considering obstacles of today’s dynamic LNG industry and ways of overcome them

Read more

State-of-the-art LNG manufacturing

Take a look inside the manufacturing process at our Port Manatee facility, as we produce world-class equipment for your specific needs.

Looking for a small LNG plant with a simple design and low unit cost?