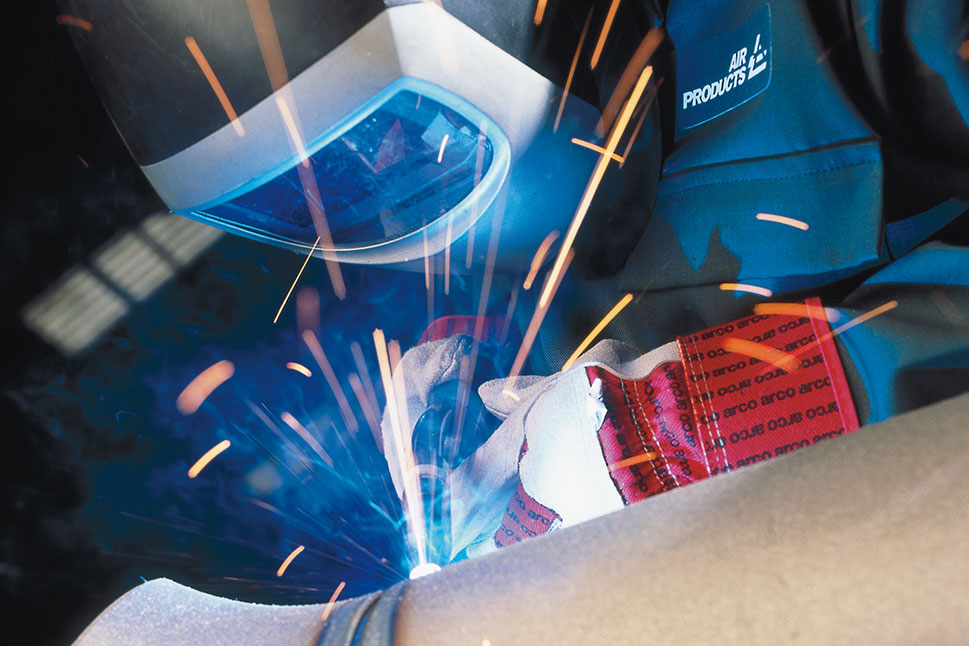

Seeing is believing:

Get expert advice and experience our gases for welding carbon steel, stainless steel or aluminum at your site.

Get expert advice and experience our gases for welding carbon steel, stainless steel or aluminum at your site.

Welding and Metal Fabrication Specialist

Base material thickness is probably the most important variable. Welding on thicker materials requires more penetration; therefore, choosing the correct shielding gas mix and wire is critical.

Air Products offers a full range of standard shielding gases for MIG/MAG and TIG welding for all common material types. These are available in cryogenic liquid vessel sizes to meet all of your welding needs. Our unique range of shielding gases has been designed following rigorous testing under real working conditions. They offer the highest levels of performance to maximize your productivity, increase efficiency, reduce rejects, and improve your working environment. Contact us and our experienced applications team will use their knowledge of your industry and application to provide you with a supply of welding gases and a technology solution to meet your unique needs.

Save money, increase productivity and improve quality.